Zerkleinerung und

Automation

für die

Kunststoffindustrie

GETECHA – Unsere Welt ist die Zerkleinerung und Automation

Seit über 60 Jahren sind wir ein kompetenter und verlässlicher Ansprechpartner für Zerkleinerungs- und Automationsprojekte. Als inhabergeführtes Unternehmen sind bei GETECHA alle relevanten Prozesse unter einem Dach vereint:

- Konstruktion und Entwicklung an modernen 3D- und E-Plan Arbeitsplätzen,

- hohe Fertigungstiefe,

- mechanische und elektrische Montage,

- und Inbetriebnahme.

Für Ihre besonderen Anwendungen können wir Versuche in unserem Technikum durchführen. Sollte eine Standardmaschine nicht passen – entwickeln wir gerne innovative und effiziente Sonderlösungen, gemäß unserem Motto: Individualität ist unser Standard.

Aktuelles von GETECHA

Produktionsnah und energieeffizient zerkleinern

Getecha präsentiert sich auf der Fakuma als Mühlenbauer und Automatisierer

Kunststoffverarbeiter und Recyclingbetriebe mit kundenspezifisch ausgelegten Zerkleinerungs- und Kreislauflösungen auszustatten – das ist seit vielen Jahren die Mission von GETECHA. Was das konkret bedeutet und welcher Grad der Prozessautomation dabei heute erreichbar ist, das veranschaulicht der deutsche Anlagenbauer einmal mehr auf der diesjährigen Fakuma in Friedrichshafen. […]

In den Trichter und durch den Einzug

Neben der Umsetzung hoch automatisierter Materialkreislauf-Systeme für die Kunststoff verarbeitende Industrie gehört die Realisierung leistungsfähiger Zerkleinerungsmühlen seit je her zu den Kernkompetenzen von Getecha. Kürzlich entschied sich beispielsweise der Kunststoffteile-Hersteller Lechner für die Anschaffung von zwei Standardmühlen der erfolgreichen RotoSchneider-Linie des deutschen Anlagenbauers. Lesen Sie hier, wie der Zulieferer damit die betriebsinternen Aufbereitungsprozesse in seinem […]

Hydraulische Alternative für dicke Randbeschnitte

In der Folien- und Plattenextrusion fallen mitunter besonders hartnäckige Randbeschnitte an, die sich nicht umlenken und nur auf der Höhe der Extrusionslinie auf das gewünschte Zielmaß zerkleinern lassen. Um dieses Material für die möglichst effiziente Verarbeitung in Trichtermühlen zu konditionieren, muss es zunächst die Prozessstufe der Vorzerkleinerung durchlaufen. Darauf abgestimmt bietet GETECHA ein Sortiment leistungsstarker […]

Aus der Extrusion in die Zerkleinerung

Horizontal-Schneidmühlen als Prozessstufe zur Herstellung von Leichtbau-Granulaten

Hochfeste Hartschaum-Werkstoffe sind eine wichtige materialtechnische Komponente zur Realisierung moderner Leichtbau-Konstruktionen für den Flugzeugbau, die Automobil-Industrie und die Medizintechnik. Ihre Herstellung beruht unter anderem auf der Verarbeitung hochwertiger Kunststoffgranulate aus extrudierten Copolymerisat-Halbzeugen. Lesen Sie hier, warum der Einsatz einer maßgeschneiderten Zerkleinerungslösung des deutschen Anlagenbauers Getecha bei deren Erzeugung eine […]

Randbeschnitte effizient einziehen und aufbereiten

Getecha-Zerkleinerungstechnik ermöglicht Rückgewinnung von Extrusionsabfällen

Überall in der Kunststoffindustrie fließen Abfälle und Reste aus der Produktion in Aufbereitungskreisläufe und werden als Wertstoffe wiederverwendet. Damit dies in automatisierten und hocheffizienten Rückgewinnungsanlagen erfolgen kann, offeriert das deutsche Unternehmen Getecha unter anderem ein attraktives Portfolio an weitgehend standardisierten Zerkleinerungsmühlen. Lesen Sie hier, wie ein Hersteller von Antriebsriemen damit die […]

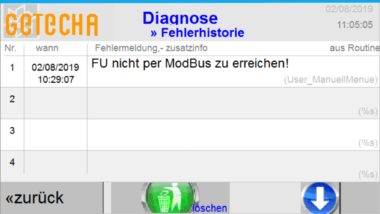

Zerkleinerungstechnik goes Industrie 4.0

Sobald Zerkleinerungsmühlen in die automatisierten Prozesse der Kunststoffverarbeitung eingebunden werden sollen, rückt auch deren informations- und kommunikationstechnische Integration in den Fokus der Planer und Automatisierer. Insbesondere die größeren Zentralmühlen seiner RotoSchneider-Baureihe stattet Getecha deshalb in zunehmendem Umfang mit intelligenten Industrie 4.0-Funktionen aus.

Zerkleinerung großer Polypropylenplatten: Vor allem seine komplexen Zerkleinerungsanlagen mit integrierten Zuführvorrichtungen, Greifern und Abluftsystemen […]